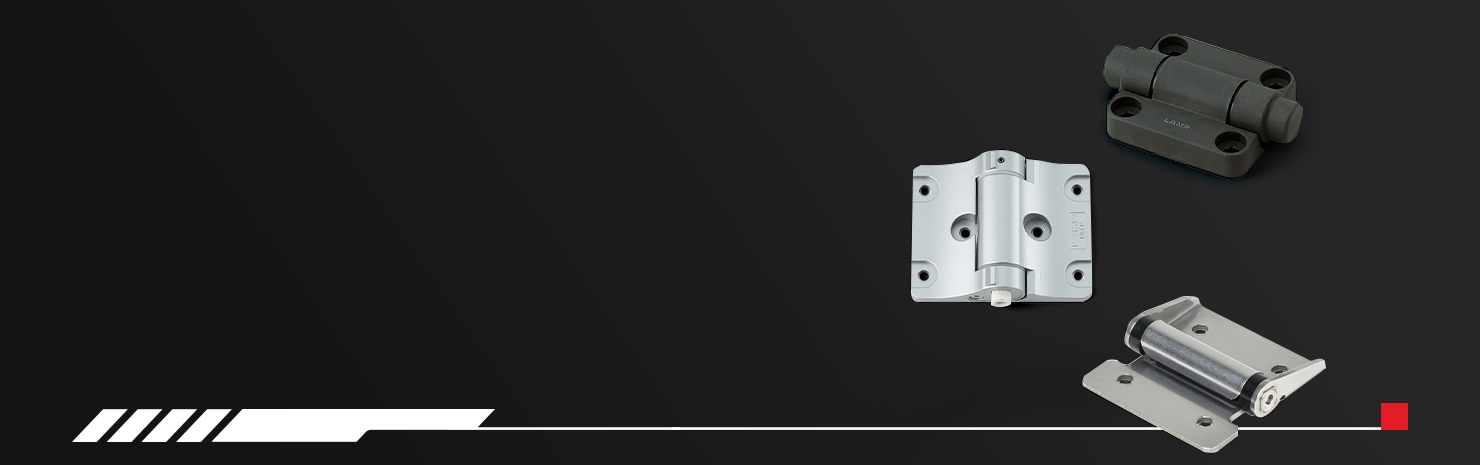

Specialty Enclosure Hinges

Enhance Your Atmosphere

Safety and convenience are some of the key variables our clients expect when it comes to selecting the best specialty hinges for their projects. Sugatsune specializes in unique hardware that provides solutions to many industries. Specialty position and movement control hinges can make your business more welcoming or your home more peaceful to guests. For medical facilities, clean room hinges help maintain a sterile environment for the safety of patients and medical practitioners.

Long-Lasting Durability

Sugatsune is AS9120 B and ISO 9001:2015 certified. We take pride in stocking over 6,000 parts ready to ship quickly, including concealed hinges, cabinet hinges, and specialty hinges. Each of our parts is built to last with quality designs that will complete your ideal space for years to come.

Consult Sugatsune Today

Consult our team for solutions to your design challenge and transform your space into a modern and functional area. View Sugatsune’s Chicago showroom online and see what our team can do for you.

FAQs

What are the key differences between butt hinges and piano hinges, and when should I use one over the other for my enclosure?

Butt hinges are the most common, and they usually feature two leaves joined in the center with a pin. Many of our butt hinges for cabinet doors are categorized as specialty hinges because of materials they are made with or how they are constructed for specialized applications. The compact design is one of the main advantages of a butt hinge. You can use it in pairs or sets of three for doors of various sizes and weights. Because the weight is distributed over a few points, butt hinges may not always work for heavy or long doors.

Piano hinges are sometimes called continuous hinges, providing a different solution. Think of a piano hinge as a very long butt hinge. It runs the entire length of the enclosure door. We like piano hinges because they distribute the load evenly across the whole seam. They’re perfect for large and/or heavy enclosures. Piano hinges are also a good choice for frequently-used enclosure doors. In terms of hinge types and mechanisms, a piano hinge offers a smooth and stable pivot point. This prevents long-term sagging.

How do torque and detent hinges differ, and what are their specific applications for enclosures?

Torque hinges and detent hinges are two types of specialty enclosure hinges. They provide specific motion control capabilities that are valuable to many modern applications. A torque hinge uses a preset friction mechanism to hold an enclosure door or panel at any desired angle throughout the hinge's range of motion. It does this without the use of a secondary support. That’s especially useful for applications where a door needs to stay open for easy access. Perhaps you have a display panel that needs to be positioned precisely for viewing. The torque hinge keeps the door or panel stable.

In contrast, a detent hinge uses a series of defined “locking” points or positions (as opposed to continuous friction). The door will only stop at several pre-determined angles. You have to apply a slight force for it to lock into the next position. Imagine a door that needs to open to one or more specific angles. One benefit of a detent hinge is that the detent at the closing position will eliminate any spring-back negating the need for a separate catch. The particular specialty hinge applications and features of detent and torque hinges make them great for controlled movement and positioning.

What is a swivel torque hinge?

A torque hinge, also known as a friction or position control hinge, is a hinge designed to provide resistance to the pivoting motion of the hinge itself. This torque hinge establishes a central axis of rotation and provides continuous holding force in a wide or full rotational axis. It provides positional retention for components that need to be aimed or turned.

This is achieved by a mechanism within the hinge that generates friction to provide resistance which prevents a component from moving unwantedly. It usually incorporates torque to hold the angle and often features a dedicated central bore for running cables.

A swivel hinge is recommended when using the free stop mechanism in the horizontal (swivel) directions, such as for rotating monitors.v