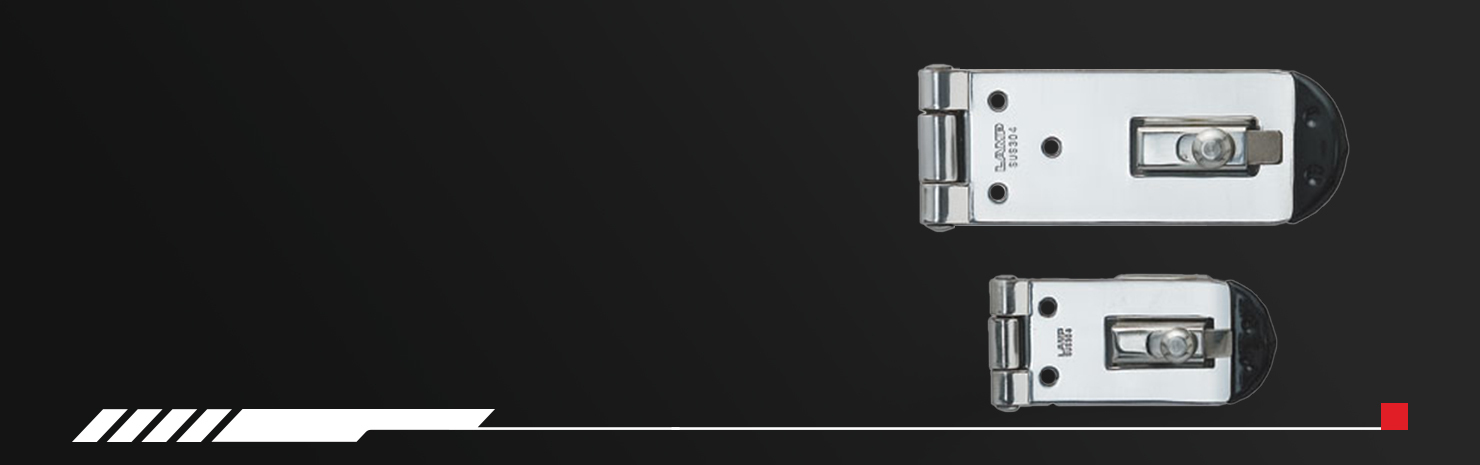

Hasps

Our Extensive Inventory of Door Hasp Hardware

Our door, gate, and cabinet hasp hardware includes stainless steel hasps, stainless steel weld-on hasps, and latching hasps. Latching hasps come with a built-in latch and are very easy to operate. Simply snap on the flap to close the hasp and slide the latch knob to release. The plastic cap on the end makes for a quieter opening sound. Whether you’re designing nautical, outdoor residential, or industrial equipment, these hardware pieces are a great choice and are NSF certified for food equipment.

A Heritage of Form and Functionality

Since 1930, Sugatsune has been a trusted source for precision-engineered hardware solutions. From architectural and furniture hardware to industrial components for industries including food, medical equipment, transportation, and aerospace, you can find the right solution to help build your creations. Sugatsune America is AS9120 B and ISO9001;2015 certified and distributes unique parts with unparalleled quality to create convenience and satisfaction for people.

Our hardware, including this selection of door, gate and cabinet hasps, supports the work of the world’s foremost engineers, architects, design professionals. Learn more about each product by consulting our digital resources, featuring product literature, or contact our experts to find the right solution to meet your application’s specification.

FAQs

What are the key distinctions between different types of hasps, and which is best suited for high-security scenarios?

Hasps are versatile closure components. You can use them to secure a simple cabinet as well as to protect a sensitive industrial enclosure. The most common types of hasps include:

- Hinged/Straight: Traditional, two-piece configuration where the hasp plate is hinged to the mountain surface. It swings over a separate staple (i.e., the loop).

- Swivel: Features a staple that swivels or rotates; best reserved for applications where the closing surfaces are not perfectly aligned. They are also recommended for rounded corners.

- Safety/concealed: Generally recommended for high-security applications. When closed and used with a padlock, the mounting screws/bolts are entirely covered.

A concealed hasp is optimal, especially when made of stainless steel and used with through-bolt fixings. In such a configuration, the weakest points in the assembly are out of sight. This is essential for high-security use cases.

What specialized hasp features and functionalities should an engineer or detailer consider, especially to optimize performance in harsh environments?

As a detailer or specifier, you’ll prioritize hasp features and functionalities that promote durability and operational efficiency:

- Materials/Finish: Stainless steel hasps are a must-have for corrosive environments, such as marine or chemical facilities. Stainless steel is superior for resisting rust and pitting, noting that 316 Grade stainless should be used in Marine applications. This is crucial for maximizing the longevity of the hardware.

- Concealed: Inaccessible fixings (screws or bolts) when the hasp is clocked or locked maximizes security. This is ideal for reducing the risk of tampering or unauthorized removal. Consider this a non-negotiable for the security of valuable or hazardous contents.

- Weld-On types: Models intended for weld-on applications also offer a permanent and tamper-proof attachment.

Another feature to consider is the quality of the hinge, which is essential for long-term function. A non-removable or welded hinge pin is best for a precision hasp, as the hinge cannot be driven out. Smooth operation under a high cycle count is another quality to look out for in demanding environments.

Which features are most critical to specific hasp applications and use cases?

The special features of a hasp are vital in any application where failure to secure an enclosure can cause significant safety hazards or security breaches. Here are a couple of example industries and use cases:

- Marine/Naval: Extreme corrosion resistance is key for securing hatch covers and electrical cabinets on watercraft. Additionally, dependable performance in high-vibration and high-salt environments is crucial. Look for a 316 grade stainless steel hasp that is low-profile and weldable.

- Food/Beverage: Hasps should be easy to clean and resistant to bacteria. Polished, stainless steel hasps with crevice-free designs work well for locking clean-in-place panel doors and storage lockers. For use in back or front of the house applications in restaurants or food services equipment, NSF-certified Hasps should be used.

- Transportation: Side-access doors on trailers and utility vehicles call for a tight seal to withstand constant road vibration. They also need to deter theft. Heavy-duty hasps that are load-rated and vibration-resistant should be detailed for this use case.

What mounting/installation considerations should I be concerned about?

Ensure the surface is properly prepared with correct flatness and support while ensuring that mounting screws/fasteners must be compatible with the surface you are applying it to. If using a weld-on version, ensure proper welding specs and post weld finish to maintain corrosion resistance.

Verify that the hasp’s “keeper” (loop/eye part) aligns correctly and permits the padlock shackle clearance and confirm that the padlock size and shackle fit into the locking eye dimension (if specifying, don’t forget to specify the padlock geometry).

How do you service or maintain hasps?

Periodic visual inspection to verify that the hasp remains securely mounted with screws remaining tight or that all of the welds are intact. If in the outdoors or corrosive environments, make sure that the finish hasn’t degraded or doesn’t show signs of rust. If so, you may want to consider upgrading to 316 grade stainless steel.

You will also want to check the operation of it to ensure that the flap/keep opens and closes smoothly. If any misalignment occurs, re-align them to avoid unnecessary strain.

If your hasp is made from stainless steel, avoid using cleaners that contain bleach or any cleaning products that contain sodium hypochlorite.